|

| May 17, 2016 | Volume 12 Issue 19 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

ESCATEC designs an innovative motor control for surgical drill

Switzerland-based ESCATEC, one of Europe's premier providers of contract design and manufacturing services, has designed a novel motor control for a surgical drill for one of its customers. The challenge was to create a motor control that is very precise because it involved medical procedures.

"In this particular case, we had to design a means of being extremely accurate with the control of the drill motor," says Christian DŁnki, ESCATEC's Lead Architect for Medical Applications. "In addition, we had to create a solution to allow starting the motor through load ranges from free run up to high torque, including stall detection and active stop, plus an oscillation mode with very low angle drift."

ESCATEC's solution used a sensorless, brushless DC motor, because it is maintenance free, requires no expensive sensors, has higher efficiency, produces no carbon dust, is smaller, and there is no electrical sparking.

The precision motor control was achieved by applying a specially written, speed-dependent, rotor-position detection algorithm. Combining this position detection, including an additional algorithm to detect the rotor position at standstill, with different PWM (Pulse Width Modulation) control schemes, enables the motor to be controlled independently of the applied mechanical load, inclusive of stand-still during direction change. The controller is in open-loop mode only during the first phase of the ramp-up. Afterwards, the position detection is used to calculate the power to reach the requested speed.

In addition, ESCATEC designed the battery-protection circuitry that ensures that the battery lasts for its expected lifetime. Combining this software-controlled protection circuit with an external charging device enables the battery to be safely charged to its full capacity, and the capacity calculated and stored into the motor controller's memory as a battery condition indication.

"Our solutions for customers are often innovative enough to be patentable," says Michael Walser, ESCATEC's Head of R&D. "Any patents usually become the property of the customer to provide them with unique selling points and protection against competitors."

ESCATEC is one of the few EMS companies to have ISO 13485 for the design and manufacture of medical devices, and it develops medical device software according to IEC 62304. The ESCATEC Group provides fully integrated electronic and mechatronic design and manufacturing solutions for many European and North American OEMs.

A look at the signals

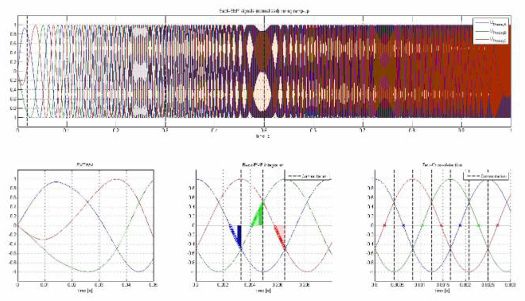

Figures showing the back-EMF signals of the accelerating motor.

The lower left figure shows the back-EMF (ElectroMotive Force) signals during the beginning of the ramp-up. During this phase, SVPWM (Space Vector Pulse Width Modulation) is used to start the motor's rotation.

The figure in the middle shows the back-EMF signals where the back-EMF voltage is integrated and the result is used to distinguish the commutation point.

The right figure shows the back-EMF signals where Zero-Cross-Detection is used to measure the position. The back-EMF voltages are measured and analyzed by detecting the zero-cross event of one motor phase at a time.

Source: ESCATEC

Published May 2016

Rate this article

View our terms of use and privacy policy